BLOG

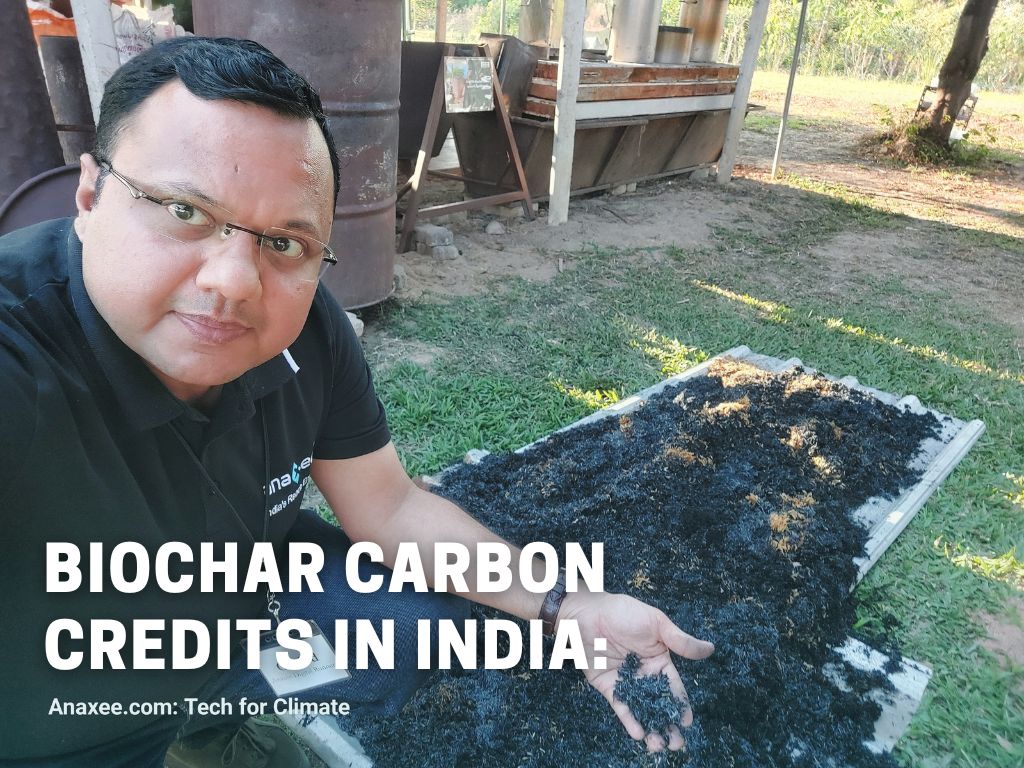

Biochar Carbon Credits in India: A Practical C-Sink Guide for Farmers & Climate-Focused Businesses

Biochar Carbon Credits in India: A Practical C-Sink Guide

India torches 35 million tonnes of crop residue every year, fuelling winter smog and wasting a valuable resource. Converting that biomass into biochar under the Global Artisan C-Sink standard locks carbon away for centuries, improves soil health, and generates a new revenue stream through voluntary carbon markets. This article explains how smallholders and project developers can move from open burning to certified carbon removal.

Why Biochar & Why Now?

Policy push: India’s Crop Residue Management Scheme and state‐level subsidies back biochar pilots in Punjab, Haryana, and Maharashtra.

Buyer pull: Big corporates-Google among the latest-are contracting long-term offtake for high-durability removal credits.

Agronomic gains: Trials show 8–15 % yield boosts and better water retention when biochar is incorporated at 2–5 t ha⁻¹.

Step-by-Step to C-Sink Certification:

| Stage | Field SOP (what auditors check) |

| Feedstock Eligibility | Record each batch of paddy straw, cotton stalk, bagasse, or coconut shell. Moisture must be ≤ 30 %; primary forest biomass is banned. |

| Drying & Storage | Sun-dry residues in ≤ 10 cm layers for 72 h and stack in airy sheds. This prevents methane emissions that could offset carbon gains. |

| Pyrolysis | Use drum or Kon-Tiki flame-curtain kilns at ≥ 680 °C. Photo-document start, peak flame, and quench to show continuous clean combustion. |

| Yield & Lab Tests | Measure output by bucket or bag, label with QR codes, and send composite samples to an ISO-17025 lab to confirm ≥ 70 % fixed carbon and H/C < 0.4. |

| Digital MRV | Upload GPS-tagged photos, kiln logs, and lab results to a C-Sink-compatible app. Sentinel-2 imagery and random spot checks validate acreage and biomass flows. |

Community & Environmental Benefits:

Income uplift: Credits trade at US $45–65 t CO₂e; a 500-t year-1 project can gross US $22–32 k, shared with farmers through residue purchase or revenue-split models.

Cleaner air: Eliminating stubble burning cuts PM2.5 spikes in the Indo-Gangetic Plain, improving public health.

Jobs in villages: Each kiln cluster needs 6–8 trained operators plus local self-help groups for bagging and record-keeping.

Circular nutrients: Nutrient-infused quench water (cow-urine slurry, compost tea) turns biochar into a slow-release fertiliser, reducing chemical input costs.

Quick Launch Checklist-

Secure biomass: MoUs with FPOs for at least one crop cycle.

Select kiln technology: Drum kilns (~₹7 k) for pilots, metal Kon-Tiki for scale.

Train operators: One-day artisan course covering safety, temperature control, and sampling.

Set up digital MRV: Choose a mobile app that syncs offline data and generates registry-ready reports.

Line up lab capacity: Identify the nearest NABL facility and pre-book slots.

Plan co-benefits: Document how the project will reduce burning, create jobs, and enhance soil health—key for buyers doing ESG due diligence.

Biochar turns an annual pollution headache into a climate-positive business case. By following C-Sink’s clear SOPs-feedstock control, high-temperature pyrolysis, rigorous lab testing, and transparent digital MRV- Indian farmers and developers can tap a fast-growing market for high-integrity carbon removal credits while delivering tangible benefits to rural communities. If you are planning a Pilot Project, Start with a feasibility assessment of your local biomass supply and kiln costs, then map out the steps above for a smooth certification journey. To know more Connect with us at salese@anaxee-wp-aug25-wordpress.dock.anaxee.com.